CeRam-Kote Product Line

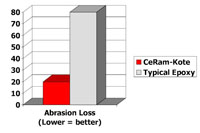

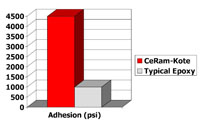

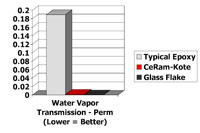

CeRam-Kote 54 For use in the toughest environments to protect expensive equipment. Excellent corrosion barrier, high adhesion, low permeability, sliding abrasion resistance, high surface lubricity, flexible, and is a fast, one-coat, two pass spray application. No primer needed.

CeRam-Kote 54 SST® has been formulated to be applied over marginally prepared substrates and rusty steel surfaces. It can be used over itself or as a primer under high performance topcoats, or as a barrier coat or universal primer. CeRam-Kote 54 SST offers outstanding adhesion even if the substrate isn’t blasted! It is tolerant of moist/damp surfaces and suitable for use in USDA inspected facilities.

CeRam-Kote 2000 Chemical resistant novalac ceramic/epoxy coating recommended for critical service. A derivative of CeRam-Kote 54®, CeRam-Kote 2000 is highly crosslinked to perform well in a variety of aggressive immersion service environments. Fast, one-coat, two pass spray application. No primer needed.

CeRam-Kote 2000TL CeRam-Kote 2000TL is a thin-film, spray-applied and air-dried ceramic novalac epoxy coating system engineered to provide excellent acid immersion service protection to all metals, fiberglass reinforced plastics, concrete and plastic substrata. CeRam-Kote 2000TL is highly cross-linked to provide superior chemical resistance. The product may be force-cured with heat for enhanced performance in extremely harsh environments.

CeRam-Kote Marine Thin-film, spray-applied and air-cured ceramic epoxy coating system recommended for atmospheric corrosion/light abrasion resistance as well as non-chemical immersion service in a marine environment.

CeRam-Kote 60 CeRam-Kote 60 / CeRam-Thane 200 System - Two-coat system is specifically engineered to provide atmospheric corrosion control where UV protection and cosmetics are important

CeRam-Kote 99 Recommended for atmospheric corrosion/light abrasion resistance as well as non-chemical immersion service. Not designed for critical service areas of high abrasion, heavy impact and/or chemical service. Fast, one-coat, two pass spray application. No primer needed.

CeRam-Kote 99M Thin-film, spray applied and air-cured ceramic epoxy coating system recommended for use where water spotting is a problem. Not designed for critical service, areas of high abrasion/heavy impact and/or chemical resistance.

CeRam-Kote 99P Thin-film, spray applied and air-cured epoxy coating system recommended for use as a protective coating for recreational and industrial pools.

CeRam-Grout GC Advanced ceramic/epoxy grouting material designed to handle the toughest corrosion pitting problems in steel and the most difficult cracking and spalling problems in concrete. Non-shrinking high build material resists thermal and mechanical shock. One-pass application.

CeRam-Kote SPG Ceramic/epoxy SPRAYABLE grout designed to be a high-build corrosion barrier. As a zero VOC, two-component, 100% solids-by-volume coating, CeRam-Kote SPG provides a non-shrinking surface after application.

CeRam-Kote SPG22 Advanced 100% solids ceramic/epoxy material designed to be trowel- or squeegee-applied on floors. Ideal for secondary containment applications. Non-shrinking high build material resists thermal and mechanical shock. One-coat application. Available in grey or off-white

CeRam-Kote SPG89 Technically advanced ceramic 100% novolac epoxy material designed as a high-build corrosion barrier. Ideal as a brushed or rolled application which levels out to a very smooth surface with no shrinkage.