CeRam-Kote FAQs

1. What is the difference between a paint and a coating?

Paint is normally classified as a cosmetic film that gives limited protection from corrosion for a limited amount of time. Paint is usually a one-component system that cures when exposed to oxygen, moisture, UV light, or the evaporation of solvent or water. Coatings and linings are tough long-term films that are generally generated through chemical reactions between two or more components and provides long lasting, tough, corrosion and sometimes abrasion resistant films for long-term protection of surfaces.

2. What is a CERAM-KOTE coating?

CERAM-KOTE coatings are coatings that utilize various highly modified resins. These resins are then loaded with different types of ceramic particles to achieve the attribute needed, whether that be abrasion, chemical or corrosion resistance. CERAM-KOTE coatings encapsulate surfaces with a ceramic shell that protects the surface from its particular environment.

3. Why should I use a CERAM-KOTE coating versus the system I'm using now?

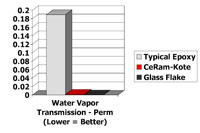

CERAM-KOTE is a coating material designed and formulated to be economical and environmentally friendly. Its ability to be applied in two passes without a primer makes it more economical to use when comparing to other coating systems on a price per square foot (square meter) applied cost. It saves money while CERAM-KOTE’s outstanding chemical and mechanical performance properties provide long-lasting protection to the substrate. CERAM-KOTE coatings are formulated to have low Volatile Organic Compound content, too.

4. What is CERAM-KOTE coating's technical advantage?

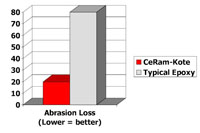

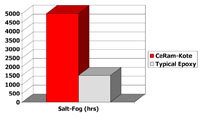

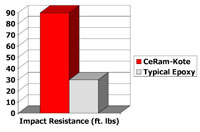

CERAM-KOTE coatings are applied direct to the substrate (i.e., no primer is needed). This saves time and money. CERAM-KOTE coatings also provide protection from chemical, corrosive and abrasive environments beyond the chemistry of the typical epoxy systems.

5. Over what substrates can CERAM-KOTE coatings be used successfully?

Carbon Steel, Stainless Steel, Aluminum, Brass, Titanium, Galvanizing, Plastics, Concrete, Fiberglass.

6. How can CERAM-KOTE coatings have so many applications in so many industries?

Due to the unique chemistry and characteristics of its inert ceramics, CERAM-KOTE coatings can be applied to just about any properly prepared surface and provide a protective barrier to that surface. Regardless of the industry, (chemical, corrosion and abrasion) problems exist. CERAM-KOTE coatings can help solve those problems.

7. Are CERAM-KOTE coatings a one or two part system?

Most CERAM-KOTE coatings are considered two component systems. Part A (base) is a ceramic/epoxy solution that is mixed with Part B (curing agent). Please see each individual Product Data Sheet for mixing and application instructions.

8. If you are out in the field with a two-component CERAM-KOTE coating, could you take the two-component kit and mix half of it in the field? Is it easy to split a two-component kit of CERAM-KOTE coating or can the splitting be detrimental to the coating?

With extreme care, a two-component kit of CERAM-KOTE may be broken down into smaller quantities. Careful and exact measurements must be made to assure that the proper ratio of Part A to Part B by volume or by weight is maintained. If split accurately, there will be no detrimental effects to the coating. However, this practice is not recommended. If it is necessary, we recommend calling Freecom’s Technical Service.

9. What is the maximum amount of thinner that can be used with CERAM-KOTE? What type of thinners can be used with CERAM-KOTE? At what temperature do you recommend adding thinners?

Due to the high loading of ceramics in the CERAM-KOTE coatings, only a small amount of the total solution is epoxy and the epoxy is the only ingredient that may be thinned. Each formula requires different amounts, but on average, each product can be thinned up to 10% by volume. Preferably, warm up the coating in the can before applying in order to eliminate the need for thinning. If thinning is deemed necessary, see the specific Product Data Sheet for recommended solvents. As the temperature of the coating decreases, the viscosity will increase. Always adjust spray equipment before extra thinning. Thinning dilutes the high solids of CERAM-KOTE and creates excessive overspray. In some cases, more than 10% thinner may be needed. Please contact Freecom Technical Service before thinning more than 10% by volume. Excessive thinning can cause some color change in bright colors, such as yellow, orange or red.

10. What is the square foot (square meter) coverage of CERAM-KOTE coatings?

These values are theoretical coverage numbers and depend on weather conditions, complexity of the substrate, and application technique:

Coating Material Theoretical Coverage

(at Spec Thickness)

CeRam-Kote 54® ATM @ 10 mils: 128 sq. ft. (12.0 sq. m.)

CeRam-Kote 99 @ 10 mils: 120 sq. ft. (11.0 sq. m.)

CeRam-Kote 2000 @ 10 mils: 128 sq. ft. (12.0 sq. m.)

CeRam-Kote SPG @ 40 mils: 40 sq. ft. (3.7 sq. m.)

CeRam-Grout GC @ 40 mils: 40 sq. ft. (3.7 sq. m.)

CeRam-Kote 60 @ 8 mils: 160 sq. ft. (15.0 sq. m.)

11. What type of spray equipment may be used to apply CERAM-KOTE?

Any type of conventional, airless, HVLP, or cup gun works well on most of the CERAM-KOTE coatings.

12. Can CERAM-KOTE coatings be rolled?

Yes. A short nap roller (approx. 1&Mac218;4” or 6.35 mm) of good quality is recommended. The shorter the roller nap, the lesser the stipple effect.

13. Can CERAM-KOTE coatings be rolled or brushed for touch-up?

Yes, as long as the surface is prepared and is free of contamination.

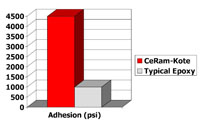

14. Why doesn't CERAM-KOTE require a primer?

CERAM-KOTE‘s ability to adhere to a substrate is one of its major advantages. If applied over a primer, the adhesion strength is only as good as the adhesive strength of the primer. Adhesive strength is much higher using CERAM-KOTE alone without a primer than it is with a primer. In addition, the elimination of a primer eliminates the cost associated with the use of that primer and makes the use of CERAM-KOTE more economical.

15. Will CERAM-KOTE coatings adhere to old coatings that are in good shape such as urethanes?

Freecom does not recommend coating over old coating as the adhesion will only be as good as the old coating. If cleaned properly to remove all contaminants, CERAM-KOTE coatings will adhere to old coatings. Care must be taken as CERAM-KOTE coatings may soften old coatings and cause them to blister and disbond. If the old coating disbonds, then any of the CERAM-KOTE coatings, which adhere to the old coating, will come off with the old coating. CERAM-KOTE coatings will adhere to sound urethanes, but if applied over enamels, CERAM-KOTE coatings will act as a paint stripper. Apply test spot if unsure of system.

16. If CERAM-KOTE is applied over enamels or acrylics, will it cause them to soften?

Yes, CERAM-KOTE coatings will cause enamels or acrylics to soften.

17. What is the absolute minimum surface preparation acceptable for CERAM-KOTE coatings?

All of the CERAM-KOTE coating systems call for a white metal (NACE 1, SSPC-SP5, Swedish Standards SA-3) finish. Each CERAM-KOTE coating system calls for specific anchor profile specifications. Please refer to each individual Product Data Sheet for more anchor profile information. Freecom, Inc., does not recommend less than a near white (NACE 2, SSPC-SP10, Swedish Standards SA-21&Mac218;2) finish. Adhesion strength depends on proper preparation of the surface to be protected. Cleanliness and profile are the most important steps to producing a coated surface that will perform and last.

18. Can any CERAM-KOTE coating be built up to dry film thickness greater than its specification to solve problems in certain situations?

With all CERAM-KOTE coatings, flexibility will decrease with an increase of thickness. If flexibility is not an issue, then this can be considered, depending on the need. Call Freecom Technical Support when contemplating thicker applications than recommended.

19. Under what upper and lower temperature limitation can CERAM-KOTE coatings be applied?

CERAM-KOTE epoxy urethane coatings should not be applied below 40°F (4.4°C) or to a surface temperature above 120°F (49°C). If the temperature is below 40°F (4.4°C), the catalytic reaction is halted between Part A and Part B. If the temperature is above 120°F (49°C).

20. What are your weather conditions or limitations for the application of CERAM-KOTE coatings (low and high)? What happens when CERAM-KOTE is applied on a day with 95% humidity?

Unless in a controlled environment, coating will only be permitted during daylight hours when air and substrate is above 40°F (4.4°C). No coating will be permitted when steel is wet from rain or dew, when surfaces are less than 5°F (3°C) above the dew point and holding or when the relative humidity is greater than 85%. In some CERAM-KOTE systems, moisture will inhibit the catalyst reaction in the coating system and will not cure or perform properly.

21. Can CERAM-KOTE coatings achieve a high gloss finish?

Due to the heavy loading of ceramic particles and solids into our CERAM-KOTE coatings, a true high gloss cannot be achieved with CERAM-KOTE epoxy coatings. Only CERAM-KOTE urethanes, although loaded with ceramics as well, can achieve high gloss. A semi-gloss may be achieved with proper application and curing techniques (CERAM-KOTE 54N, CERAM-KOTE 2000 and CERAM-KOTE 99 formulas have better gloss retention than CERAM-KOTE 54®). Several variables are involved in achieving the maximum gloss when using CERAM-KOTE epoxies:

- Cleanliness of the supply air to the spray equipment can determine gloss (no moisture is allowed for maximum gloss).

- Temperature and time can also determine amount of gloss. Accelerated cure schedules using ovens or externally applied heat within 10-20 minutes of application will be necessary to achieve maximum gloss.

- If cured in cold temperatures as low as 40°F (4.4°C) and the temperature goes through the dew point as temperature rises or decreases while CERAM-KOTE 54® or CERAM-KOTE 99 are still wet, the coatings will have a flat finish due to the moisture condensation on the surface of the coating.

- If a high gloss finish is necessary, we recommend using CERAM-THANE 300 or CERAM-THANE 200.

22. What is the dry to handle time of the CERAM-KOTE coatings?

Dry to handle time is totally dependent upon the temperature of the day and/or the environment. The higher the temperature, the shorter the time needed before the coating may be handled. The colder the temperature, the longer it will take before the coating may be handled. At ambient temperature, 72°F (22.2°C), CERAM-KOTE epoxy coatings will typically be dry to the touch usually within 3 hours if mixed. CERAM-THANE urethanes will be dry to the touch within 7 hours.

23. How long does it take for CERAM-KOTE epoxy coatings to cure? How soon after coating can the object coated be put into service?

A 70% cure will occur at ambient temperature, 72°F (22.2°C), within 12 hours, at which time the coating may be placed into service if it is not an immersion or extremely harsh environment. If the coating is to be exposed to an immersion service or a harsh environment, the best possible scenario is to allow 7 days at ambient temperature for the coating to cure. This time can be accelerated if heat can be added to the coating in order to accelerate the curing. Consult Freecom’s Technical Service for additional information.

24. How does CERAM-KOTE hold up to sagging when applying in various weather conditions?

If applied in two passes as specified, CERAM-KOTE coatings will not run or sag. The colder the temperature the longer the time between passes. The solvent must be allowed to evaporate from the first coat before the second coat is applied. Solvents evaporate at slower speeds in colder climates.*

*CERAM-KOTE SPG is 100% solids, hence can be applied thicker in one pass with no detrimental effects to the coating film. Freecom can also allow other formulas to be sprayed in one pass. Please contact Freecom Technical Support for details.

25. Do you recommend CERAM-KOTE coatings be applied in two colors on the same system, i.e., a base white first pass and a gray second pass to visually guarantee appropriate coverage specification?

The use of two different colors when applying any CERAM-KOTE epoxy coating has been recommended by Freecom, Inc. where lighting is poor and exact color matches are not required, such as inside tanks. This is a good procedure to ensure that the entire surface is covered. When the same color is used for the first and second pass, it is difficult to see in poor light if the second pass has been accomplished satisfactorily.

26. How does the color of CERAM-KOTE coatings hold up to UV degradation?

CERAM-KOTE epoxy coatings use modified epoxy resin as the binder for the ceramic powders. CERAM-KOTE 54®, CERAM-KOTE 54N, and CERAM-KOTE 99 actually have good UV stability when compared to other epoxies, but they are still epoxies. CERAM-KOTE 2000 and CERAM-KOTE 60 do not have good color fastness in UV light. Epoxies are not known for their resistance to UV (Ultraviolet) light. Due to the molecular structure of epoxies, the UV light breaks down the molecular structure and causes "chalking" on the surface. This does not affect the performance of the coating in preventing corrosion for many years. Most CERAM-KOTE epoxy coatings will maintain their color and appearance for six months to a year depending on the exposure to UV*. (Colorfastness for bright reds, oranges and blues changes within three months). If color fastness is required, Freecom recommends using CERAM-THANE 200.

* CERAM-KOTE 60 must be topcoated for UV protection.

27.Can CERAM-KOTE epoxy coatings be top-coated for UV stability purposes?

Yes, CERAM-KOTE epoxy coatings can be top-coated for UV stability purposes*. Freecom recommends using CERAM-THANE 200. Freecom recommends bright colors be topcoated.

* CERAM-KOTE 60 must be topcoated for UV protection.

28. What range of colors are available in the various CERAM-KOTE coatings? Can any CERAM-KOTE coating be matched to most any color?

CERAM-KOTE 54N and CERAM-KOTE 99 have been designated as our color formulas, and can be matched in almost any color. Freecom, Inc. can match most any color. A chart of standard colors that are stocked by Freecom is available. Special colors may require up to three weeks for color match. Florescent or metallic colors must be matched in our urethanes only. CERAM-KOTE 54® and CERAM-KOTE 60 have limited color selection. CERAM-KOTE 2000 is available in Gray, Tan, or White. CERAM-KOTE SPG is only available in Gray. We recommend if color retention is needed, then CERAM-THANE 200 or CERAM-THANE 300 may be necessary.

29. Does Freecom have up-charges for certain colors? What are the color up-charges?

CERAM-KOTE’s price is established based upon Freecom's standard color of grey. The costs of some of the pigments are extremely high. Example: Standard grey pigment is about $3.00 per pound. A red, orange, blue or yellow pigment may cost as much as $15.00/$20.00 per pound. The reason for this high cost is the elimination of heavy metals from the pigment formulations for environmental safety. Freecom cannot absorb this increased price for the special pigments; therefore, an up-charge is placed on these special colors.

30. What is the in-service life of CERAM-KOTE coatings? (What is its life expectancy?)

Each application has its own life expectancy depending on the severity of the environment. CERAM-KOTE coatings have been in extremely hostile environments in the oil industry for over ten years. In many applications, CERAM-KOTE coatings have been protecting equipment for several years. The environment is a factor for in-service life of the coating.

31. Can CERAM-GROUT and/or CERAM-KOTE SPG be used in conjunction with other CERAM-KOTE coatings as a heavy duty abrasion resistant system?

It is difficult to achieve good cosmetics with the use of CERAM-GROUT. If a good cosmetic surface is desired after filling holes with CERAM-GROUT, the surface of CERAM-GROUT should be prepared by sanding and then a topcoat of any CERAM-KOTE epoxy coating can be applied over the grout. CERAM-KOTE SPG does leave a very good cosmetic surface.

32. Do CERAM-KOTE coatings have any other tougher anti-skid system for use in extraordinary tough abrasive environments.

Yes. Contact Freecom for more information.

33. What are the volume solids of the CERAM-KOTE coatings?

CeRam-Kote 54®: 80% +/- 2%

CeRam-Kote 99: 75% +/- 2%

CeRam-Kote 2000: 80% +/- 2%

CeRam-Kote SPG: 100%

CeRam-Grout GC: 100%

CeRam-Kote 60: 80% +/- 2%

34. What is the VOC rating of the CERAM-KOTE coatings?

CeRam-Kote 54®: 1.63 lb/gal (196 g/liter)

CeRam-Kote 99: 1.65 lb/gal (198 g/liter)

CeRam-Kote 2000: 1.56 lb/gal (187 g/liter)

CeRam-Kote SPG: 0 lb/gal

CeRam-Kote 60: 2.0 lb/gal (240 g/liter)

CeRam-Grout GC: 0 lb/gal

CeRam-Kote Organic Zinc Primer: 2.6 lb/gal (321 g/liter)35. Are CERAM-KOTE epoxy coatings environmentally friendly? When cured, CERAM-KOTE epoxy coatings are designed to be as environmentally friendly as possible. Our epoxy coatings are considered food grade* and may be disposed of in any land fill. Consult your local government agency. *CERAM-KOTE 2000 and CERAM-KOTE 60 are not considered food grade.

34. What are the health hazards of the CERAM-KOTE coatings? Are they more hazardous than other high performance coating systems?

CERAM-KOTE coatings can cause skin sensitization. Freecom recommends the use of protective clothing. The use of an organic-filter respirator is recommended when using any CERAM-KOTE coating material.

35.Can CERAM-KOTE be used in potable water tanks?

Yes, but only in countries where it has received governmental approval. CERAM-KOTE 54® has been approved for use in potable water tanks in Scandinavia, New Zealand, the United Arab Emirates and the United States.

36. Where does CERAM-KOTE coating test data come from?

All of the test data generated on CERAM-KOTE 54® has been generated by independent or customer laboratories as well as documented real time tests.

37. What is Freecom's guarantee for the CERAM-KOTE coatings?

As Freecom does not have control of the application of CERAM-KOTE, Freecom can only guarantee that CERAM-KOTE is manufactured to our strict manufacturing specifications and the testing accomplished to the best of our knowledge is correct. However, it is the responsibility of the end users to determine if CERAM-KOTE will work for them.

38. What is the typical lead time in ordering and receiving CERAM-KOTE products? Is this lead time applicable to all colors and all formulations?

Typical orders for CERAM-KOTE products in Freecom's published colors may be shipped within three days (from the manufacturer), depending on quantity. Special colors that require color matching may take three weeks. This lead time applies to all formulas.

39. What are the container sizes of CERAM-KOTE coatings? How are they packaged?

Most CERAM-KOTE coatings are available in five gallon kits, one gallon kits and quart kits. Each kit contains one container of Part A and another container of Part B. They are packaged together in an internationally approved shipping container. Pint and 6.5 oz. touch-up kits are available for some products.

40. What is Universal Coating Inc.'s shipping policy? Who pays the freight?

All shipments are FOB Edmonton, Alberta, Canada. Freight is paid by the customer.